Open Automatic Control System

CPBW FlexControl™

Laboratory Drilling Fluid Parameters Automatic Detection & Simulation Analysis System—DFSL

DFS Series Products

- Why choose DFS series products?

- Drilling Fluid/Drilling Engineering Field Digital & Intelligent Service System—DFS

- Laboratory Drilling Fluid Parameters Automatic Detection & Simulation Analysis System—DFSL

- Truck Mounted DFS System—DFSTM

- Related Subsystems of DFS Series Products

- AHT System

- IFS System

- VF&VPSS

- DFSMU

DFS Series Products

- Why choose DFS series products?

- DFS

- DFSL

- DFSTM

- Related Subsystems of DFS Series Products

- AHT System

- IFS System

- VF&VPSS

- DFSMU

Laboratory Drilling Fluid Parameters Automatic

Detection & Simulation Analysis System—DFSL

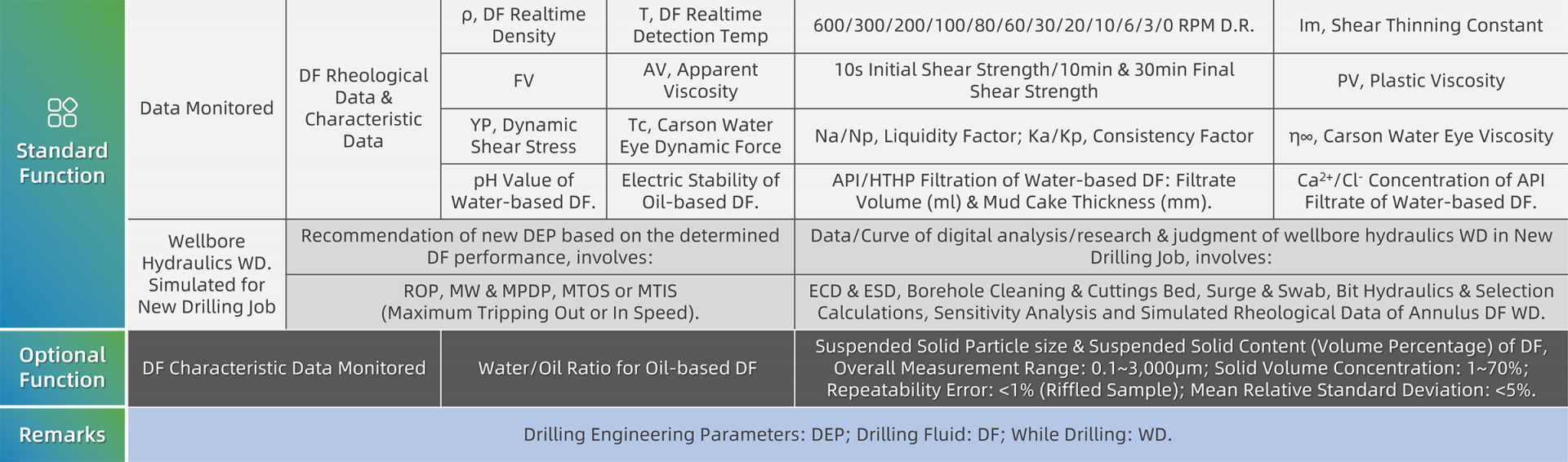

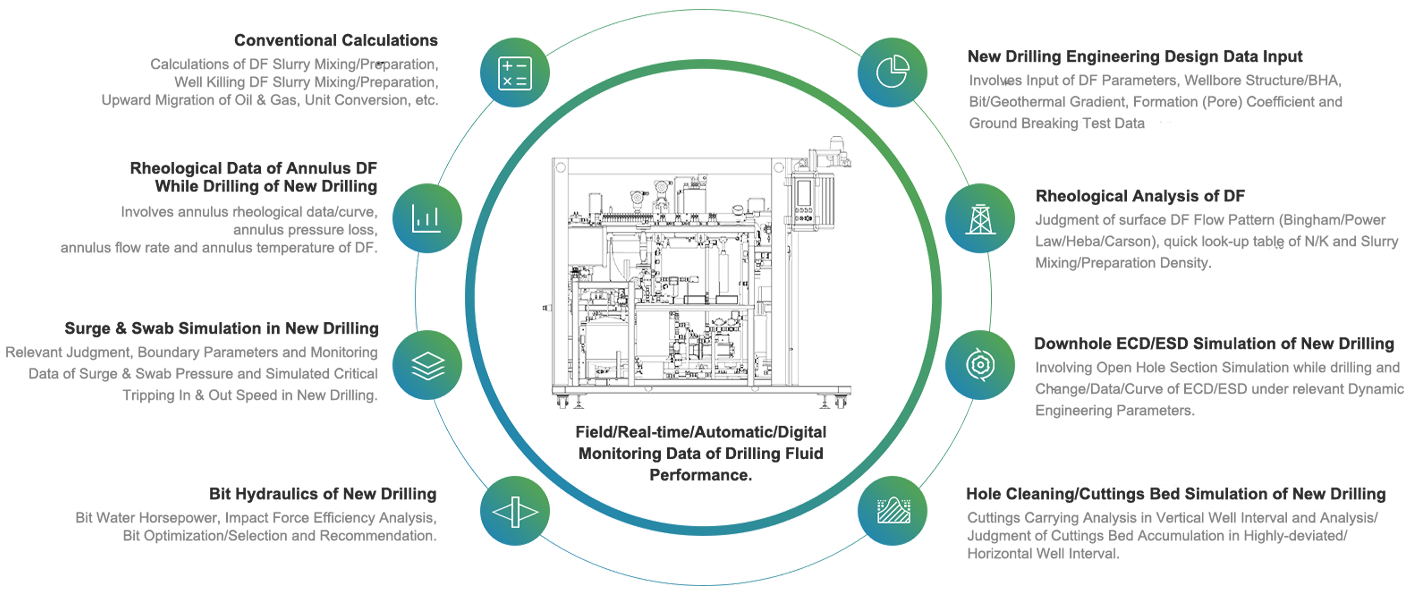

DFSL System Data Output

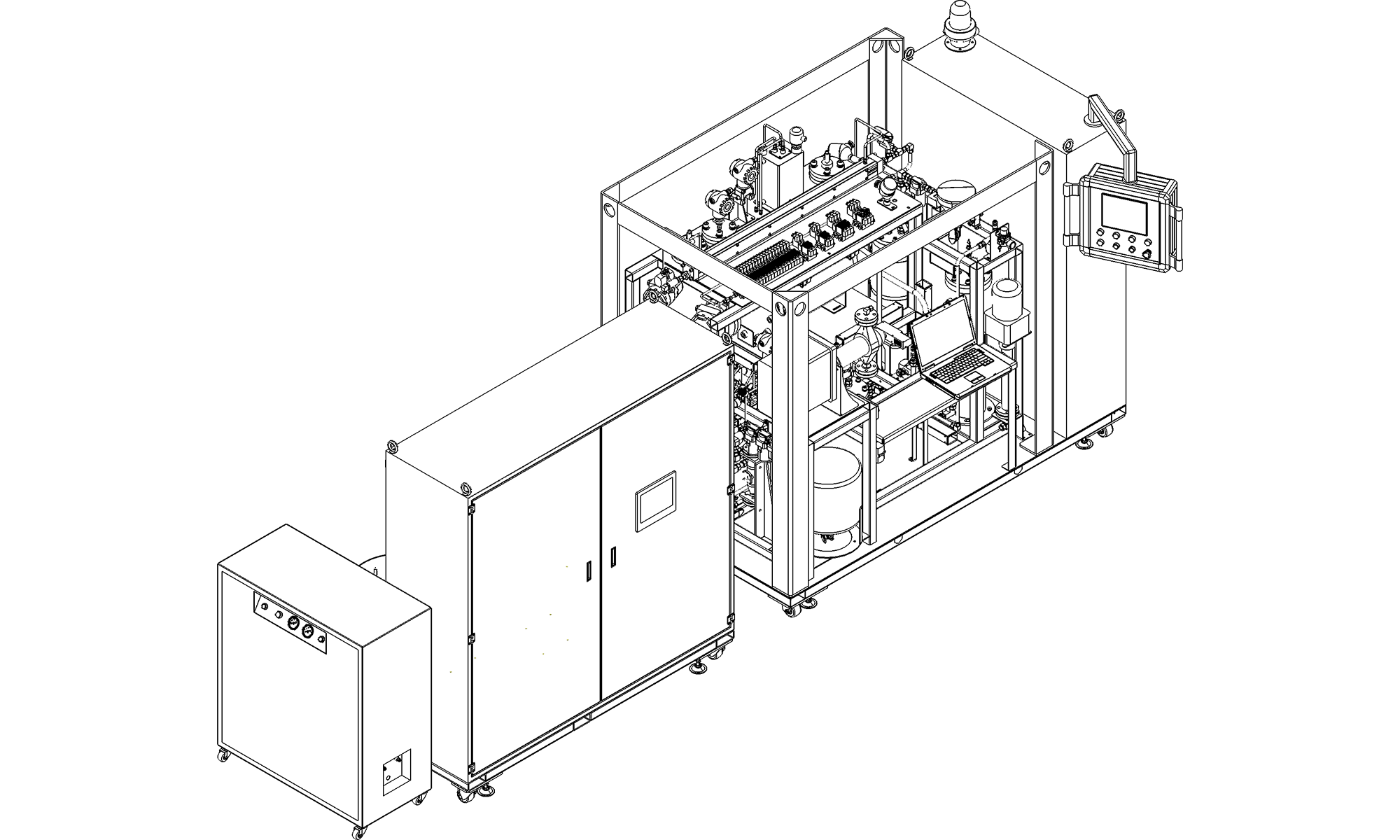

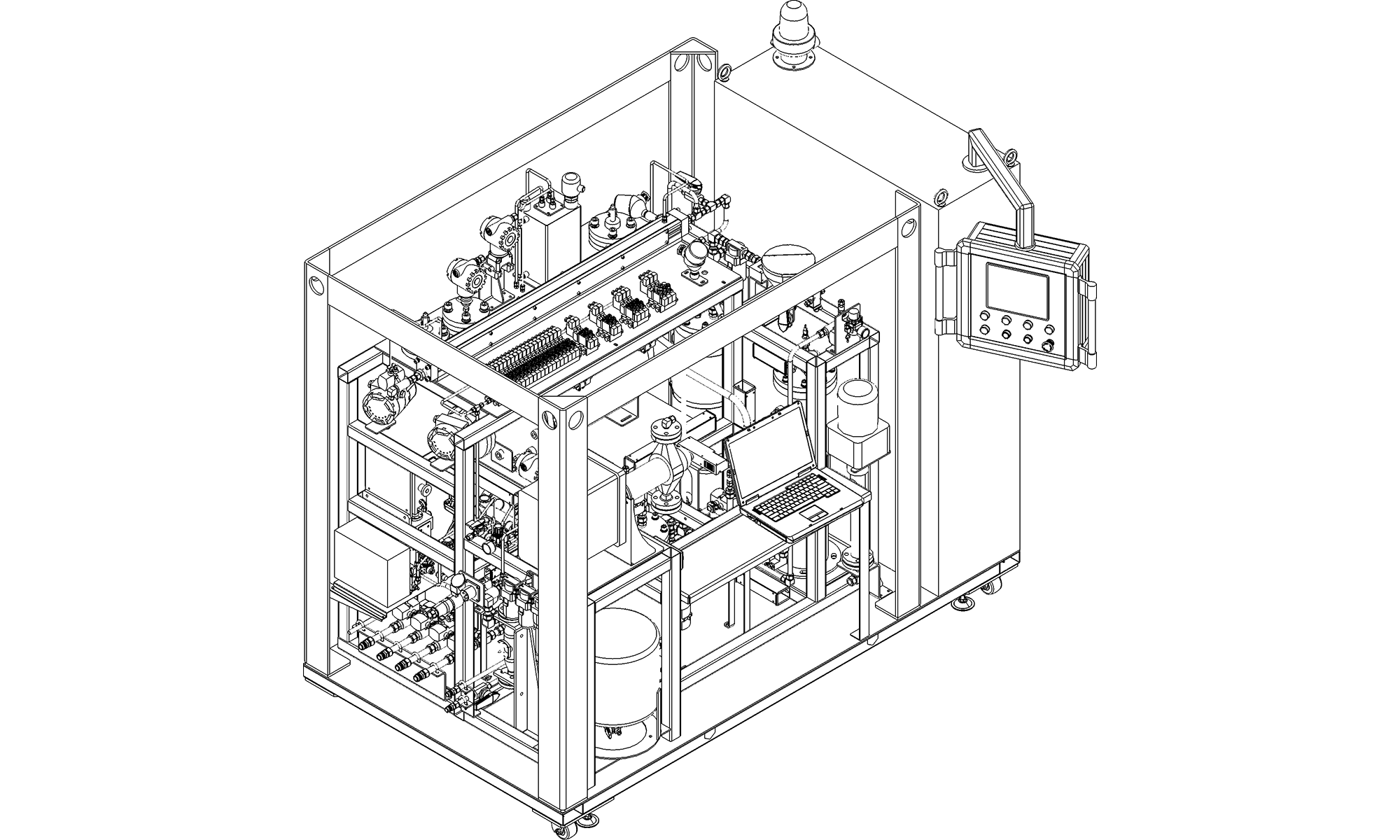

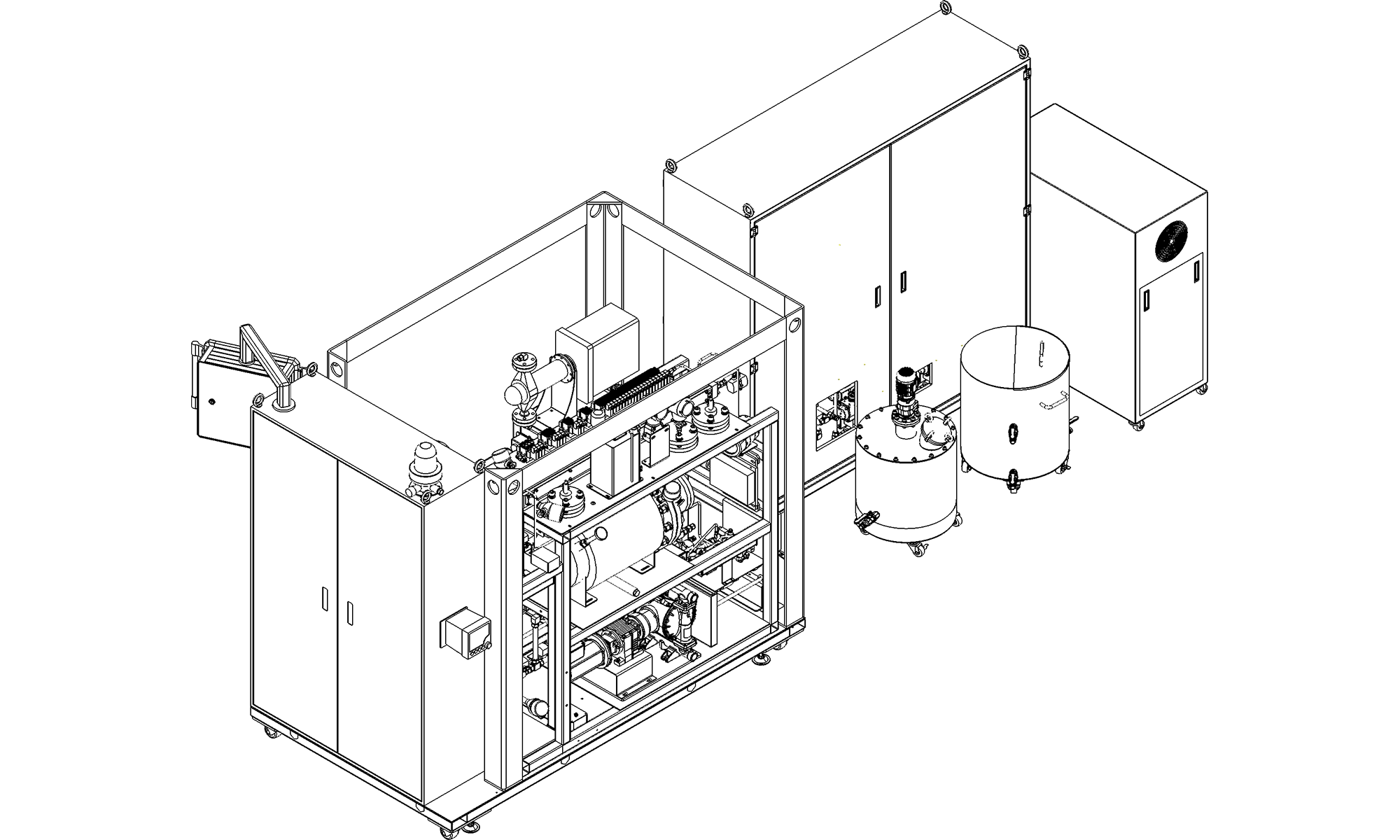

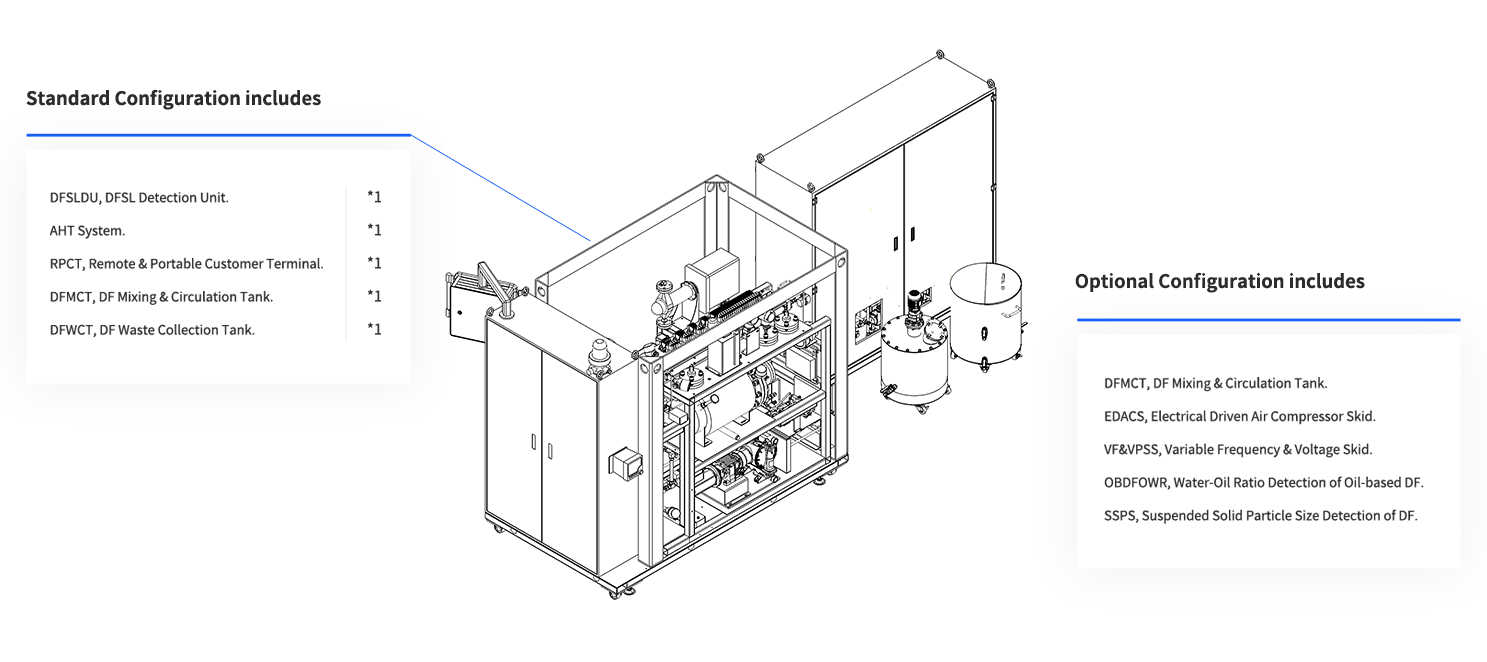

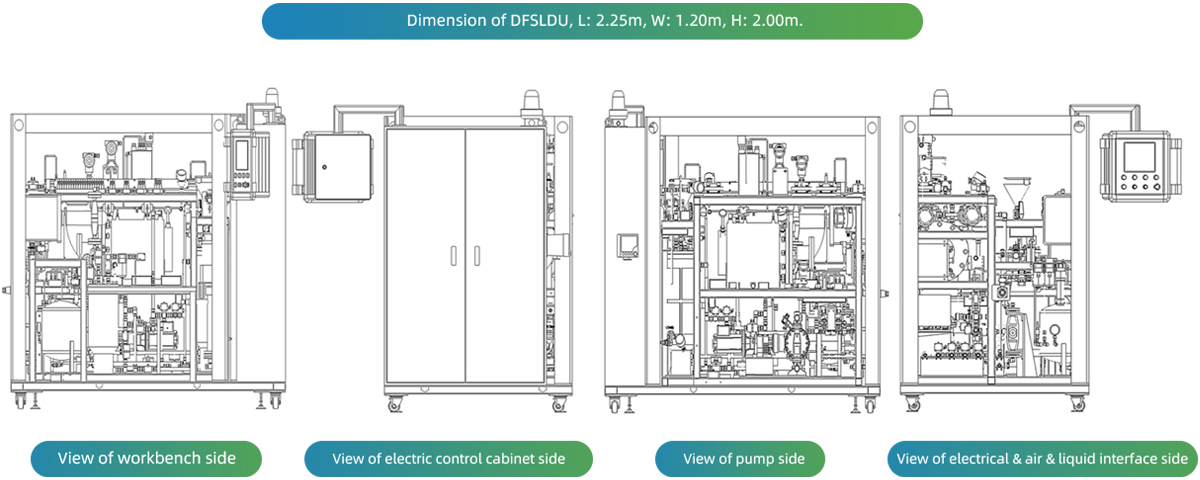

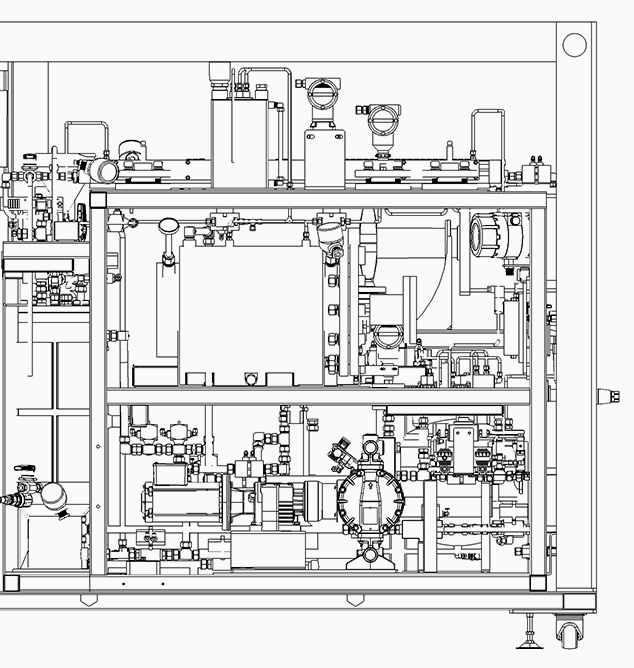

DFSL System Composition & Lab Layout

DFSL System Lab Layout

The laboratory shall be equipped with: Power Supply (AC380V/50Hz or AC460V/60Hz), Instrument Air (Pressure: 0~0.8MPa) (electric driven air compressor skid EDACs is optional) and water supply.

Standard Function of DFSL System

1

Applicable to Environmental Temperature: 0~45℃;

2

Applicable Drilling Fluid (DF) : Water-based/Oil-based/Synthetic based/Solid-free DF (Excluding special DF for plugging);

● AV = 0~150MPa·S (Recommended Monitoring temperature of Water-based DF: 50℃ & Oil-based DF: 65℃); Temperature range: 10~80℃;

● Density = 0~3g/cm³; Output Frequency: Every 5 minutes.

● AV = 0~150MPa·S (Recommended Monitoring temperature of Water-based DF: 50℃ & Oil-based DF: 65℃); Temperature range: 10~80℃;

● Density = 0~3g/cm³; Output Frequency: Every 5 minutes.

3

Ability to directly acquire multiple data and present data/curve periodically; Automatic judgment of DF Flow Pattern (Bingham/Power Law/Heba/Carson);

4

Realtime Automatic pH Value Monitoring of Water-based DF; Realtime Automatic Electric Stability Monitoring of Oil-based DF;

5

Equipped with AHT System: Automatic API/HTHP (3.45MPaDP; 100/120/150/175/200°C) Filtration of Water-based DF with Filtrate Volume & Mud Cake Thickness; Automatic Detection of Ca2+/Cl- Concentration of API filtrate;

6

RPCT is equipped to realize Remote Monitoring of DFSL and Digital Analysis & Judgment of DF Wellbore Hydraulics Simulated While Drilling in New Drilling (involving ECD & ESD, Borehole Cleaning & Cuttings Bed, Surge & Swab, Bit Hydraulics & Selection Calculations, Sensitivity Analysis and Simulated Rheological Data of Annulus DF While Drilling); Realize Engineering Simulation & Data Comparison of New Drilling for different DF properties; Realize Recommendation of new drilling engineering parameters based on the determined DF performance, including ROP, DF Density & Displacement and Max. Critical Speed of DP Tripping In & Out; Form ability of simulation/research and judgment with data support when dealing with the complex of DF engineering;

7

Full Automatic/Unattended Operation Mode from “Start" to “Stop"; Self inspection after startup of detection unit; Automatic system process “Cleaning/Purging"; Self provided DF temperature real-time monitoring & closed-loop control system; Preset Self-start/Manual Random Start; Equipment Operation Fault Alarm;

8

Data Transmission through Local Wired/Wireless Network (WITS0 Protocol, WITSML Format and TCP/IP Modbus Protocol);

9

DFSLDMDR: DFSL System Detection/Management Daily Report, which is used to record the performance parameters of the detected DF and the relevant operation status of DFSL System;

10

According to JJG1002-2005 (National Metrological Verification Regulations of PR. China) and ANSI/API 13b-1/2, all DFS Series Products complete Calibration Operation of Rheological Verification with Confirmed & Standard Lube Oil before Ex-factory, and System itself automatically generates Digital Calibration Report based on each DFSL Series Number; Follow the guidelines of ANSI/API 13b-1/2 and GB/T 16783.1/2 Standards.

DFSL System Standard Configuration Related Data Accuracy

1

Density: Nominal ACC.: ±0.002g/cm³; ACC. for DF: 0.005~0.01g/cm³;

2

Average Accuracy of Rheological Data output: ≥ 90%; Average Repeatability: ≥ 95%;

3

pH Value of Water-based DF: 0~14, ACC.: <0.3 drift;

4

AHT Subsystem: API Filtrate Volume (±0.1ml) & Mud Cake Thickness (±0.5mm)

5

Ca²⁺/Cl⁻Concentration of API filtrate:

● Ca²⁺Concentration<400mg/L, error=40~80mg/L;

● Ca²⁺Concentration>400mg/L, error<10%; Repeatability: >95%;

● Cl⁻Concentration<1000 ppm, error=100~200ppm

● Cl⁻Concentration>1000 ppm, error<10%; Repeatability: >95%.

● Ca²⁺Concentration<400mg/L, error=40~80mg/L;

● Ca²⁺Concentration>400mg/L, error<10%; Repeatability: >95%;

● Cl⁻Concentration<1000 ppm, error=100~200ppm

● Cl⁻Concentration>1000 ppm, error<10%; Repeatability: >95%.

Optional Function of DFSL System

1

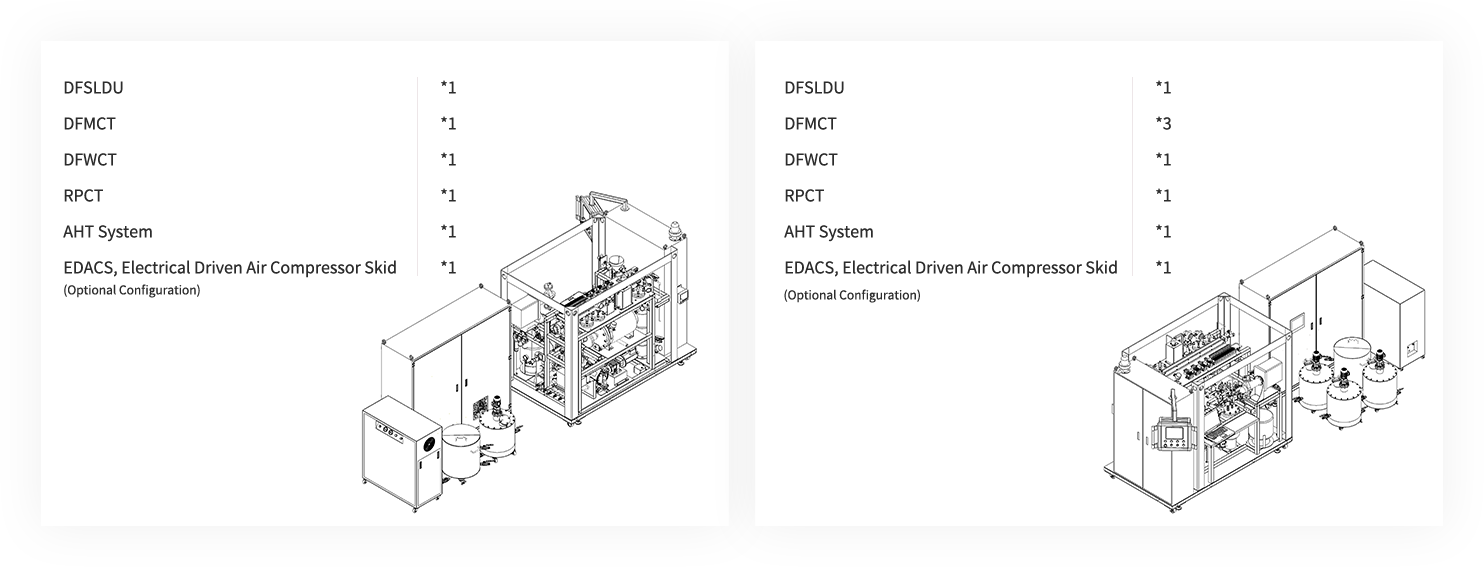

DF double suction or three suction circulation system realizes the data detection and data comparison of different DF research and preparation in the laboratory;

2

DF Mixing/Circulating Tank (DFMCT, 1~2 pieces);

3

Electric Drive Air Compressor Skid (EDACS, 1 set): Power: 2.2kW; Power Supply: 220V/50Hz; Noise: Less than 55dB (a); Output Pressure: 0~0.8MPa; Exhaust Volume: 150L/min; Oil Free Lubrication; Maintenance free and silent;

4

Water-Oil Ratio Detection of Oil-based DF (WOR): Water Content: 0~20%; Repeatability: ±0.1%; Data Qualification Rate: ≥95%;

5

Suspended Solid Particle Size Detection of DF (SSPS): (0.1~3,000μm);

6

Variable Frequency & Voltage Skid (VF & VPSS): AC380V/50Hz+AC460V/60Hz, 25KVA, IP65;

7

Remarks:

● Above 6 Optional Functions operate based on the existence of standard configuration; The Customer can choose based on standard configuration;

● There is no causal and interdependent relationship between above 6 Optional Functions.

● Above 6 Optional Functions operate based on the existence of standard configuration; The Customer can choose based on standard configuration;

● There is no causal and interdependent relationship between above 6 Optional Functions.

DFSL System Data Capability

Business Value of DFSL System Application

Greatly improve the ability & efficiency of DF development, verification and performance evaluation in various Laboratory application scenarios of DF;

Reduce personnel allocation related to DF; Reduce the consumption & loss of DF; DF R&D, verification and performance evaluation by software simulation based on Geological & Engineering Data ensure the stable applicability & clear adjustability of field batches DF to the greatest extent.

Systematically improve the scientificity, timeliness and compliance of the whole process from Laboratory DF R&D, verification and performance evaluation & judgment to field DF engineering services, so as to consolidate the technology and data foundation for realizing the Intelligent DF;

Realize the digital transformation of the whole process of DF preparation and field operation of drilling engineering, and systematically obtain the results of sustainable “Quality Improvement/Cost Reduction/Efficiency Increasing".