Why choose CPBW FlexControl?

Why choose CPBW FlexControl?

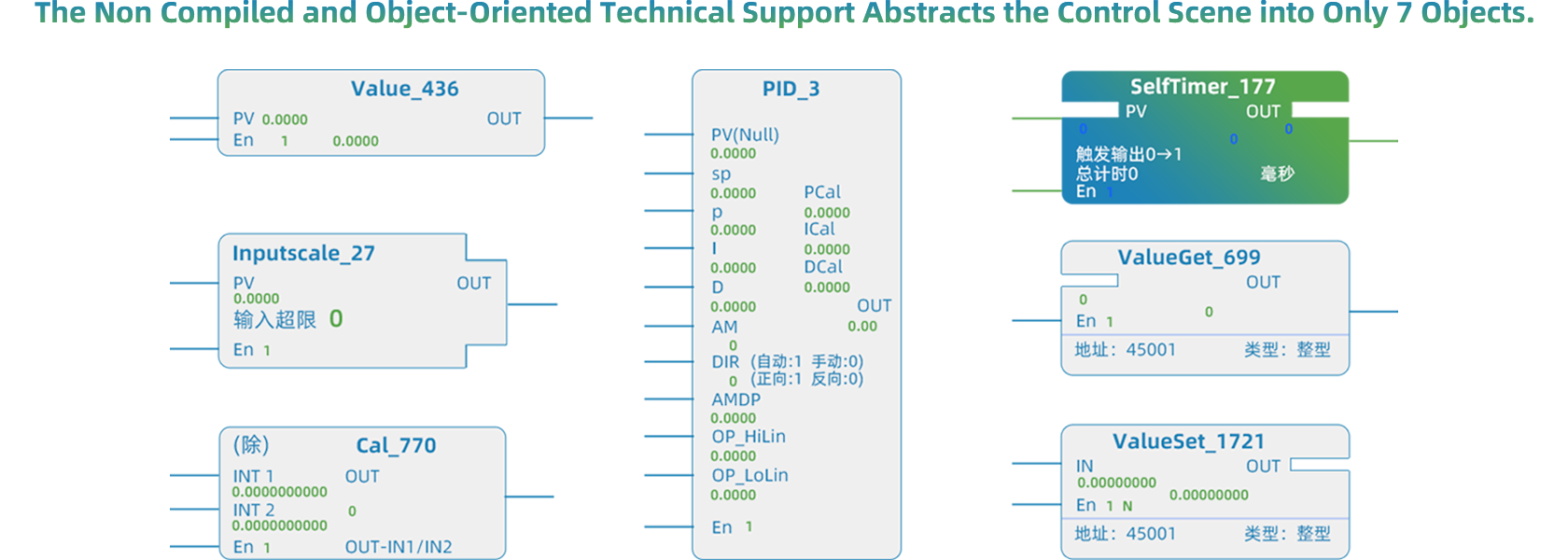

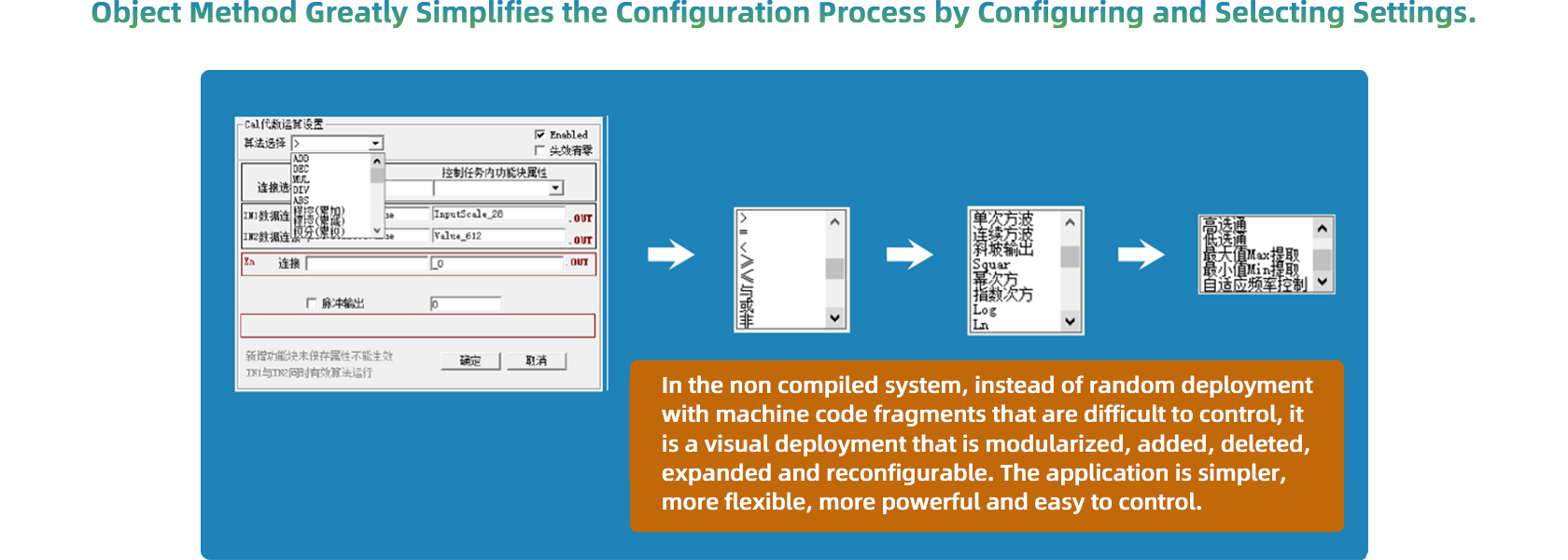

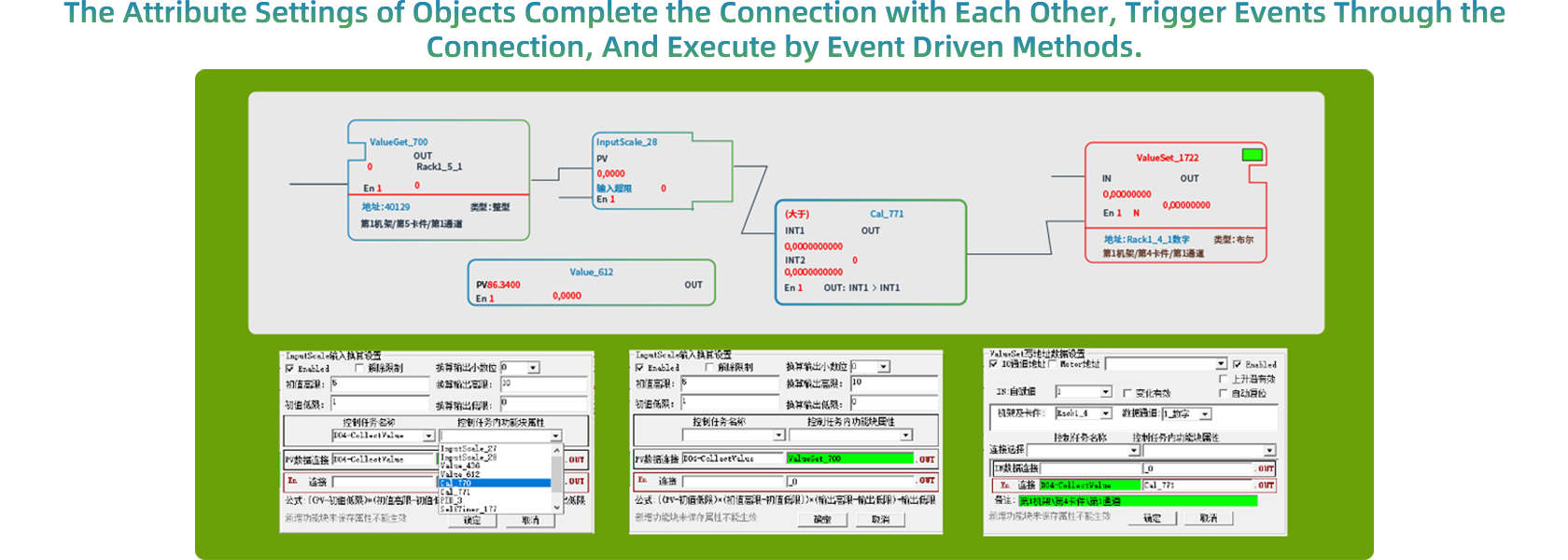

No Code Operation/Management

Software/Hardware configuration adopts graphical dragging and connection mode, and the whole process does not involve any programming problems of high-level language syntax. Realize the implementation of non compiled technology, and the configuration can be saved in non compiled form, downloaded, circulated and operated in non compiled form;

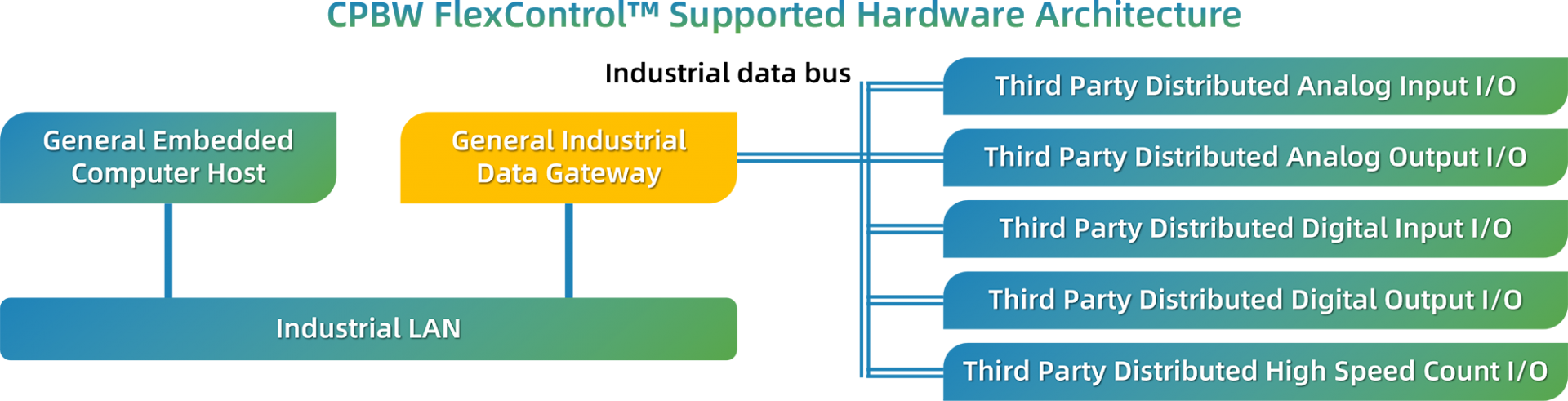

Security/Compatibility/Expansion/Configuration & Reconfiguration

The concept of fully open architecture realizes the modular and standardized integration of automatic control system controller, communication gateway and IO card from the software level, so that PC hardware, communication gateway hardware and IO hardware of different manufacturers can be compatible and combined into a complete control system, so as to realize the functional support of Expandable/Configurable and reconfigurable.

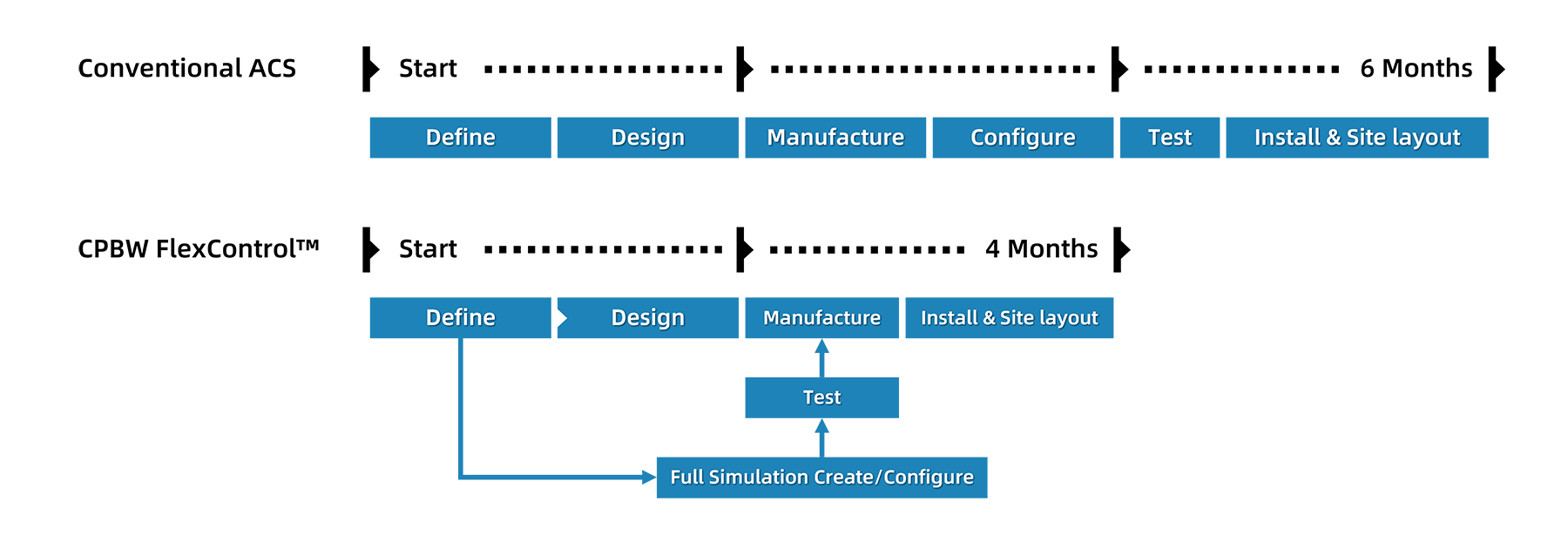

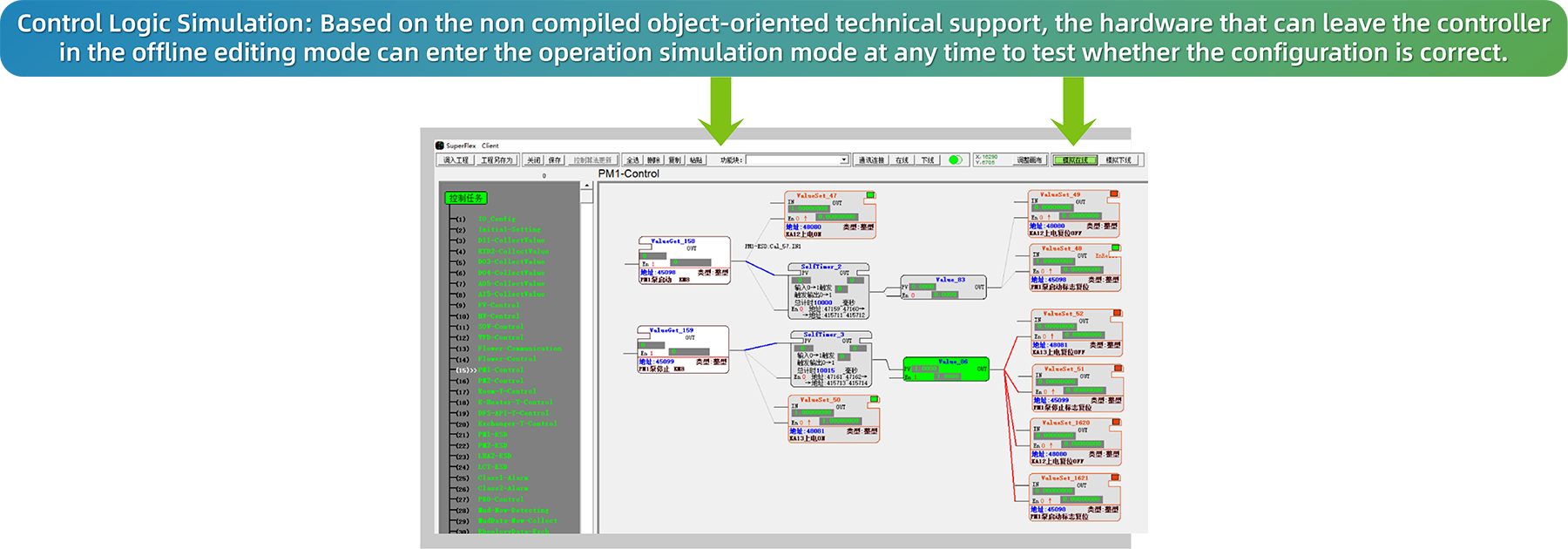

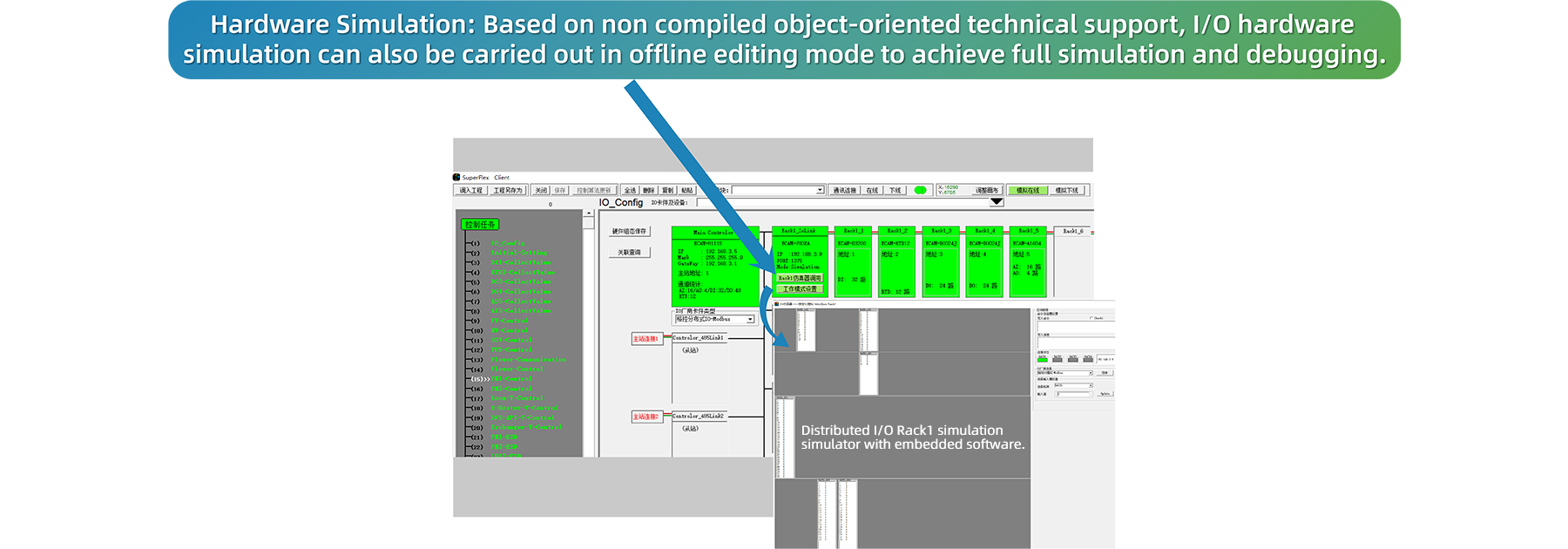

Full Simulation

Support the full simulation of off-line configuration, realize the same full scene simulation and debugging as on-site on-line application, and realize the verifiability of the control system after configuration and before actual on-site joint commissioning and test.

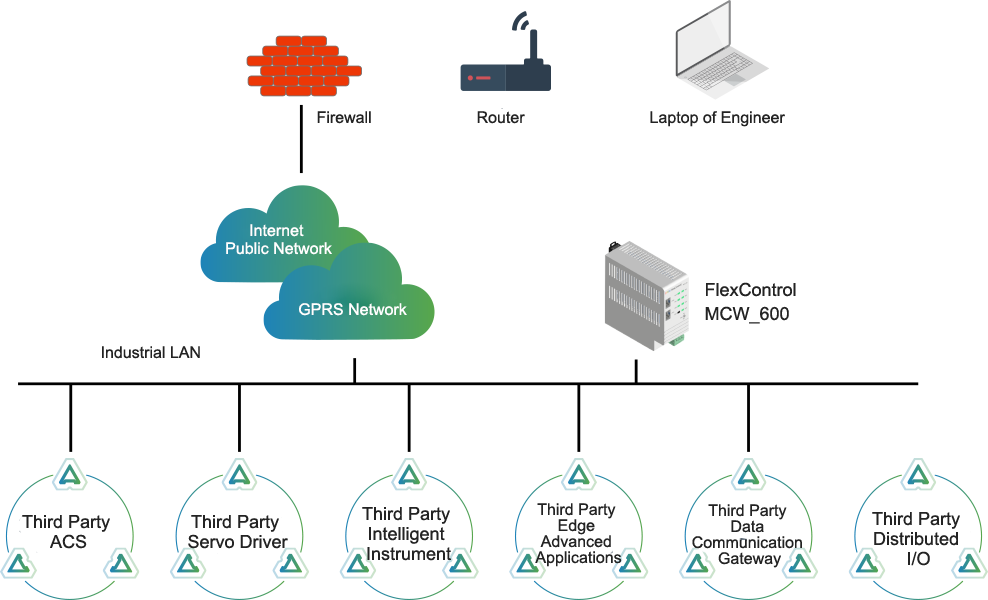

Remote Maintenance/Upgrade/Management

Support mainstream network application strategies, and have remote connection login, configuration maintenance, upgrade and management under the network environment.

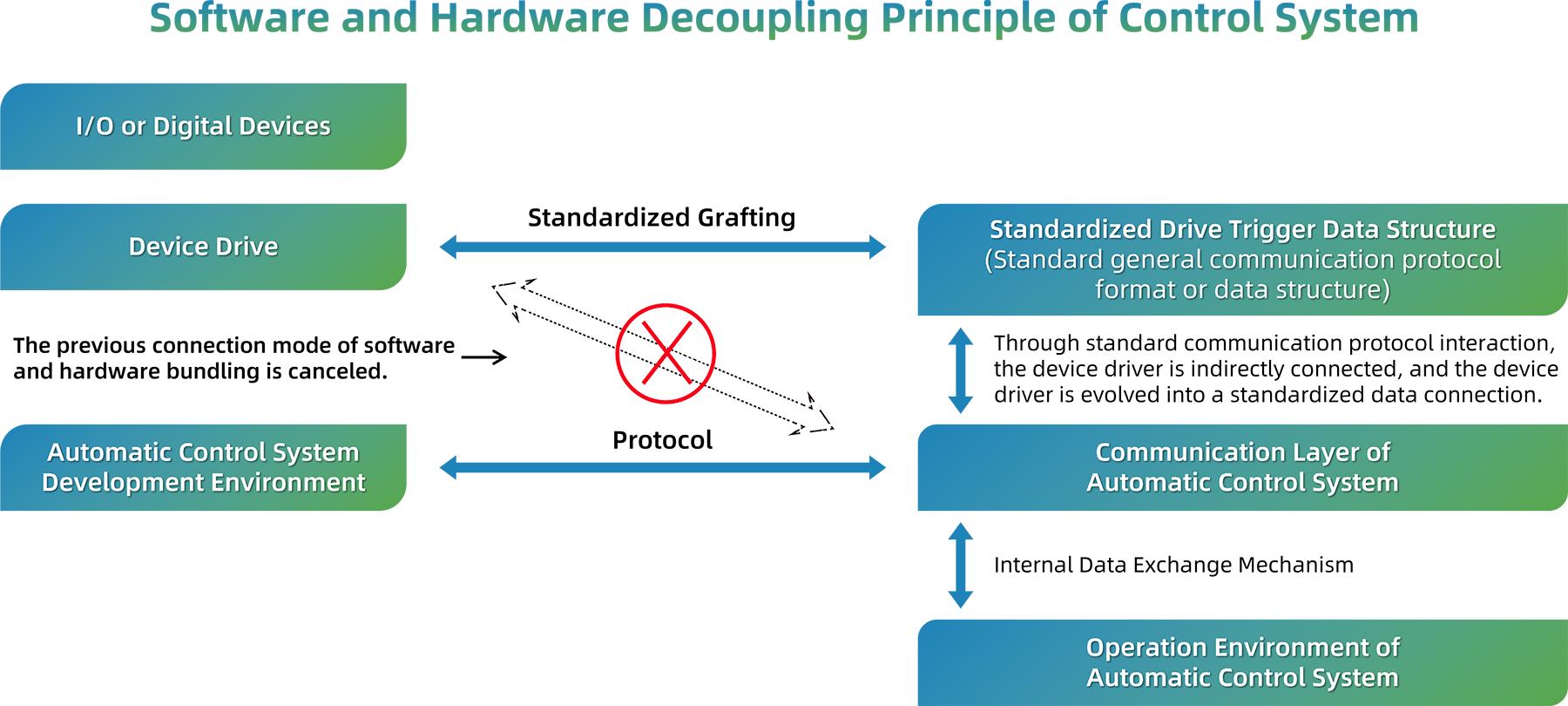

Portability, System Interoperability, Software & Hardware Decoupling

Innovative system architecture enables core software and edge computing software to interact with hardware through open standard protocols and structured data reading & writing (object-oriented data operation), without worrying about the drive and performance of hardware, so as to achieve the decoupling of Software & Hardware. Non compilation technology, realize the application of Objectification/Containerization supported by Data Structure, and realize the operation environment transplantation across software platform (Windows/Linux) and hardware platform (PC/Arm) by formulating standard Objectification/Containerization development, application architecture and data structure, so as to meet the interoperability of engineering configuration and fully realize the interoperability of ACS.

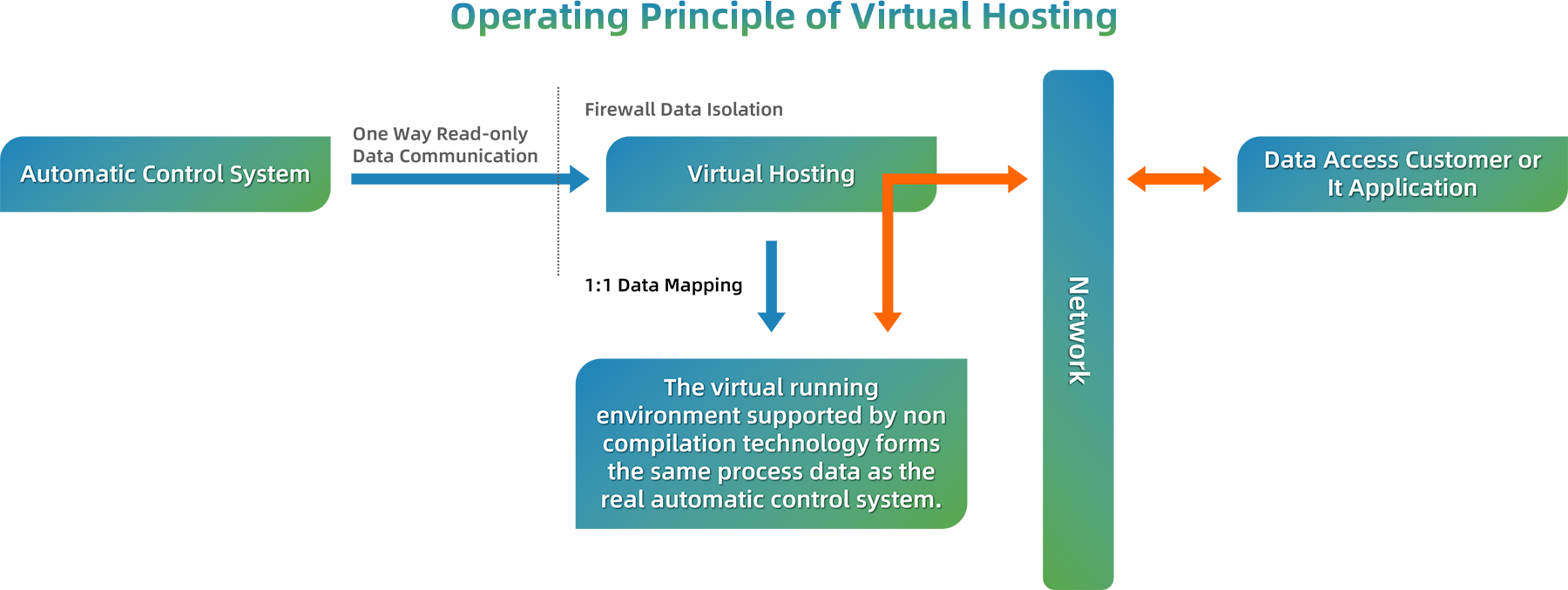

Meet the Needs of Industrial Internet and Intelligent Control Strategy

Provide integrated support for Internet connection and access, and provide hardware for Internet connection and interworking in the form of Virtual Host from the hardware level; The Virtual Host connects and exchanges data with the control system in the form of internal closed bus, and connects with the outside world in the form of network; From the software level, realize Real-time Image of Virtual Host to the data of the real control system that does not involve control logic (process data with read-only attribute), and provide it or advanced analysis data source applications.